5 Essential Elements For machining

Prototype machined enclosures created with lightening pace! Swift equipment enclosures to fit your 3D CAD knowledge and …

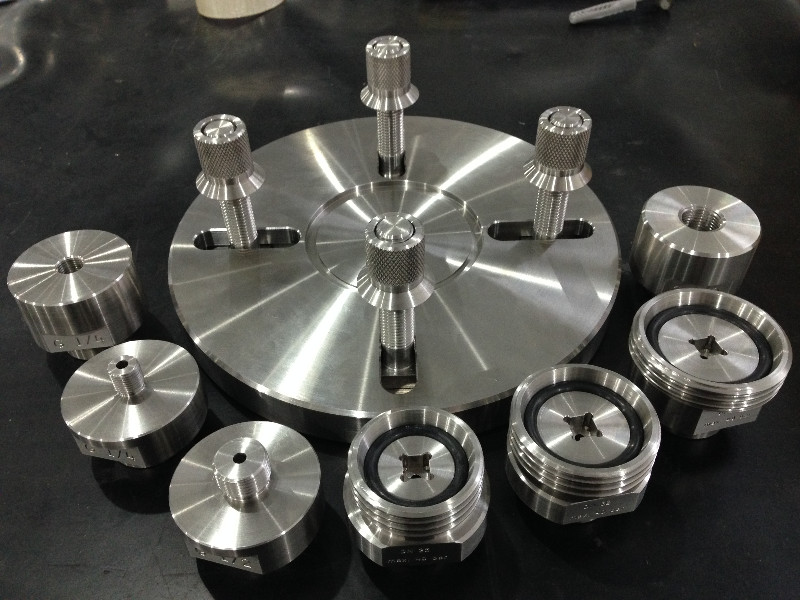

Precision machined things are all around in day to day objects including vehicle engines, electric motors or even clocks. Nations for instance Switzerland and Germany have a reputation for there large expectations of precision engineering and today nevertheless do an excellent work of it. Other nations even have a lesser of this popularity like Japan and Great Britian.

What's a precise measurement? A precise measurement is a precise measurement.How long,how tall how extensive.. Instance-12X5X24 Precision refers how close measurements of precisely the same detail are toeach other. A specific measurement is one that is similar or thesame as former measurements.

Examine This Report on machining

Ram-style mill This could certainly confer with any mill that has a reducing head mounted on a sliding ram. The spindle might be oriented possibly vertically or horizontally. In practice most mills with rams also involve swiveling means, whether or not it is termed "turret" mounting. The Bridgeport configuration is often categorised like a vertical-head ram-style mill.

We Focus on the forefront of innovation and technologies to just take merchandise from strategy all the solution to client described concluded item. Ask for a quotation.

Milling is a reducing system that employs a milling cutter to eliminate product with the floor of the workpiece. The milling cutter is a rotary reducing Device, generally with numerous slicing factors. Versus drilling, in which the Device is Innovative usinagem de precisão together its rotation axis, the cutter in milling is frequently moved perpendicular to its axis in order that cutting happens within the circumference from the cutter. Given that the milling cutter enters the workpiece, the cutting edges (flutes or enamel) with the Instrument regularly cut into and exit from the fabric, shaving off chips (swarf) within the workpiece with each move.

NC programmers can determine and solve errors in Resource paths previously and decrease programming lead occasions. With capabilities to capture and reuse greatest practice information, NC programmers can method smarter and a lot quicker whilst preserving the quality of the plans and precision on sections machined.

Due to the fact paying for a certain machining center, NIST has experienced unacceptable equipment actions during regional electrical power situations which have damaged in-process components.

5 Simple Techniques For precision machining

excellent approach creation backorder course of action set cost marginal cost

NC and CNC's drastic development of equipment Device Management deeply transformed the culture of manufacturing.[31] The details (which can be past the scope of this short article) have progressed immensely with every passing ten years. 1980s–existing[edit]

Mattress mill This refers to any milling equipment exactly where the spindle is over a pendant that moves up and down to move the cutter in the operate, although the table sits over a stout mattress that rests on the ground.

Machining requires awareness to many particulars for the workpiece to satisfy the requirements established out within the engineering drawings or blueprints. Beside the plain problems connected with correct dimensions, There's the condition of obtaining the right finish or floor smoothness within the workpiece.

Top precision machining Secrets

Throughout the close of World War I, device tool Command Highly developed in various ways in which laid the groundwork for later on CNC know-how. The jig borer popularized the Tips of coordinate dimensioning (dimensioning of all locations over the part from a single reference place); Performing routinely in "tenths" (10-thousandths of the inch, 0.0001") as an everyday device capability; and utilizing the Management to go straight from drawing to aspect, circumventing jig-producing. In 1920 the new tracer design and style of J.C. Shaw was applied to Keller tracer milling equipment for die-sinking by using the three-dimensional copying of a template.